In the wake of COVID-19, the shortages of certain raw materials and products have revealed the shortcomings in European supply chains, as well as the dependency implicit in the open nature of its economy. The EU has more to lose than other parts of the world with these shortages, interruptions and bottlenecks in its supply chains, which have an impact akin to greater global protectionism.

One of the victims of this age of scarcity seems to be the just-in-time approach to industrial and retail processes, which did so much to enhance the reputation of the ‘Toyota way’, by reducing the storage of components and parts to a minimum. It is a system that enables savings to be made but, as the pandemic has shown, that also increases manufacturers’ and countries’ vulnerability. Warehousing will again become a fact of life for factories and retailers. The World Bank claims that for many goods sold worldwide, a delay of one day is the equivalent of levying a 1% tariff. Despite all this, economies are generally buoyant, even though supply cannot keep up with the accelerating pace of demand. Globalisation starved of fuel? This is how the economist Paul Krugman seems to interpret it when he refers to ‘a world running on empty’.

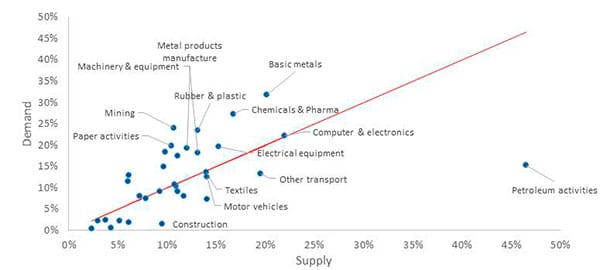

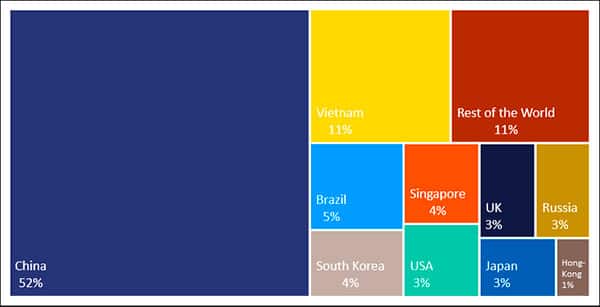

Let us start with some significant facts about these European shortages and dependencies. According to the European Commission, there are 137 products in the most sensitive ecosystems where the EU is highly reliant on imports from third-party countries. The EU is acutely vulnerable in 34 of these, owing to the difficulties of diversification and replacement within the Union. This applies above all to computers and electronic components (which includes microchips), chemical and pharmaceutical products, basic metals, electrical equipment, mining, paper, machinery, plastics, textiles, motor vehicles and petroleum activities. By value, 52% of this product dependency is accounted for by China, followed by Vietnam (11%), Brazil (5%), Singapore (4%), South Korea (3%), the US (3%) and the UK (3%) (Figure 1 and 2).

One cause for concern is that, amid a failure to anticipate this phase of the post-pandemic crisis, there has been a lack of political and economic analysis, and of the automation of processes that had burgeoned in the previous decade, even more so with COVID, and of industrial management itself. Few saw these shortages coming. The pandemic has led to manufacturing chains being severed, new workers in certain fields not being trained (lorry drivers for example), and maritime shipping becoming more expensive –80% of freight is transported by sea (although these prices have been falling since the beginning of October, according to the benchmark Baltic Exchange Dry Index)– and the shortage and rising cost of containers. According to the engineer and consultant Fernando Rodríguez, raw material prices are falling in line with falling freight costs, just as they rose when freight costs rose. From his viewpoint, therefore, it is not a matter of raw material shortages so much as of scarcity of ships and, fundamentally, scarcity of crews. This goes back to the general problem involving strenuous, poorly-paid jobs, which many people made unemployed during the pandemic now reject, another interesting issue that has received insufficient academic explanation.

In the context of these supply shortages, an analysis from the Center for Strategic and International Studies (CSIS, The Manufacturer’s Dilemma) sets out two types of solutions for manufacturers: either bringing some production back or closer to Europe (or to the US or other countries –so-called reshoring and nearshoring–); or an increase in resilience. With reshoring, suppliers reduce their dependency on global supply chains by moving production within or close to national borders. This is no easy task and requires time and resources. As far as some needs are concerned, such as the manufacture of advanced chips, there is not enough investment in Europe to compete with Taiwanese and South Korean ‘fabs’ in the short term, although there is the Important Project of Common European Interest, which is being developed for micro-electronics and goes some way to redress this.

According to the European Commission, resilience is ‘the ability not only to withstand and cope with challenges but also to undergo transitions in a sustainable, fair and democratic manner’. And this is precisely the situation we are in, because we are creating a paradigm shift, owing above all to the digital and green transformations. Supply change resilience is defined as its ability to withstand and respond to interruptions, minimising the time needed to restore operating capacity. In other words, resilience gauges the capacity of a supply chain to re-establish the output levels preceding the interruption.

Trade as a proportion of GDP grew between 1999 and 2019 from 31% to 54% in the Eurozone, whereas in the US it grew from only 23% to 26%. As the President of the European Central Bank Christine Lagarde argued recently when she quoted these statistics, while protectionism was on the rise in other parts of the world there was relatively little in Europe. A study conducted by ECB researchers concludes that if it had not been for the supply-chain bottlenecks caused by the pandemic, Eurozone exports would have been 7% higher in the first half of 2021. For the rest of the world the figure is only 2.3%. Europe is not only more dependent on external supplies but also on foreign trade.

Hence the importance that all the proposals made on strategic autonomy and sovereignty (including but not limited to the military domain) should be open. Europe needs to safeguard its supply chains, but in an open manner. The European gameplan should be posited on interdependence –not dependence or independence– internally and externally. This is the basis of its existence. And of its growth.

Image: Empty German motorway in Cologne. Photo: Florian Schmetz @floschmaezz